Bike Technology

Whether it’s the grueling demands of long-distance road racing, the punishing demands of mountain biking and cyclocross or the exhilaration of BMX riding, Maxxis tires have become renowned as the ultimate cycle tire for enthusiasts and professionals around the globe.

We place great importance on providing cyclists with the best products possible and we are constantly striving to discover ways in which to improve and innovate the tires we offer.

The technology that goes into making every Maxxis cycle tire is intelligently and thoroughly researched, bringing you products you can trust and rely on throughout your life’s journey in cycling.

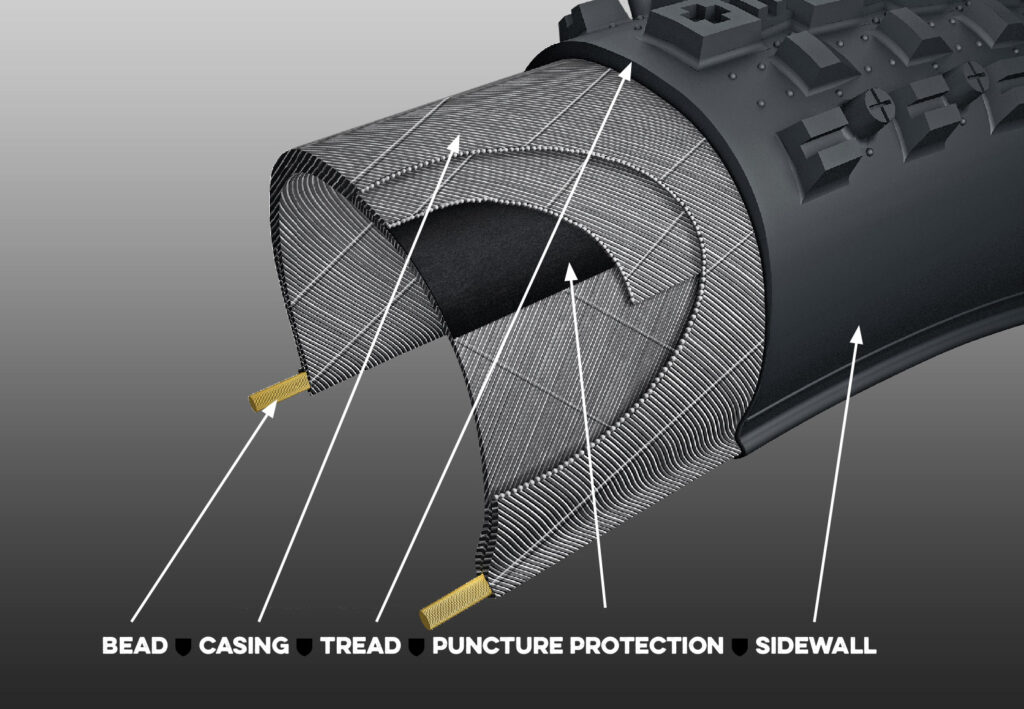

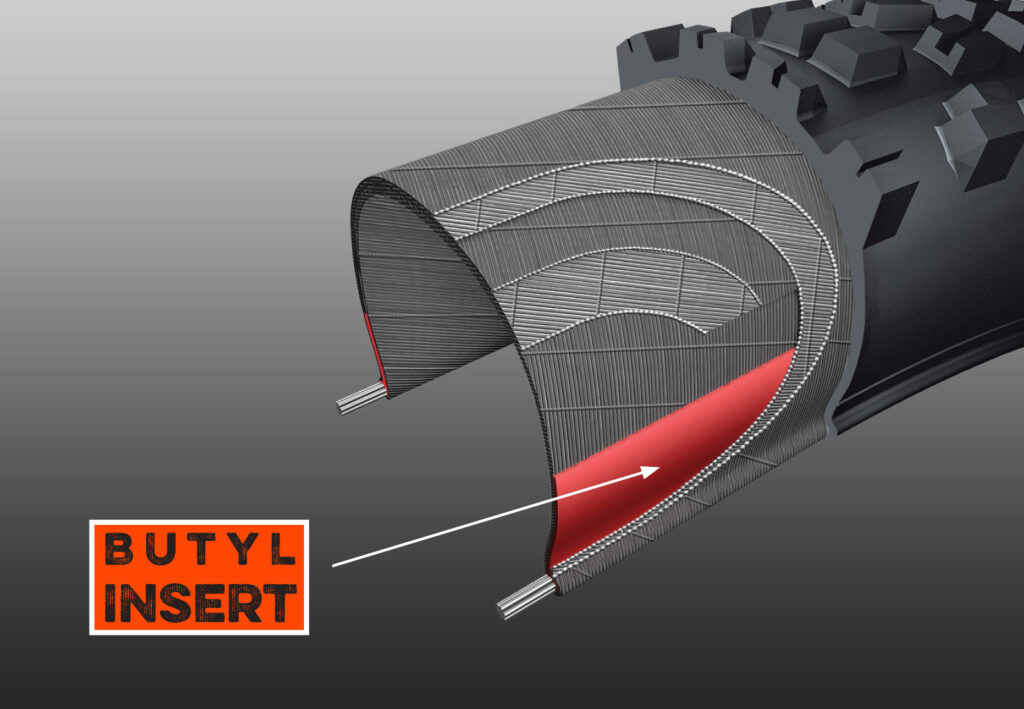

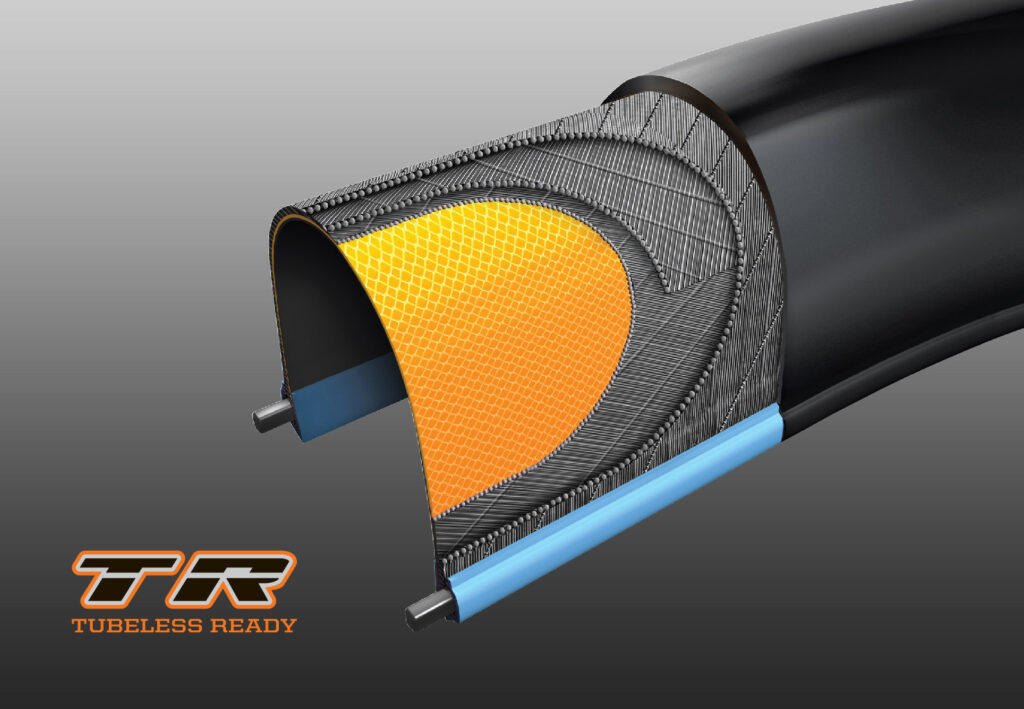

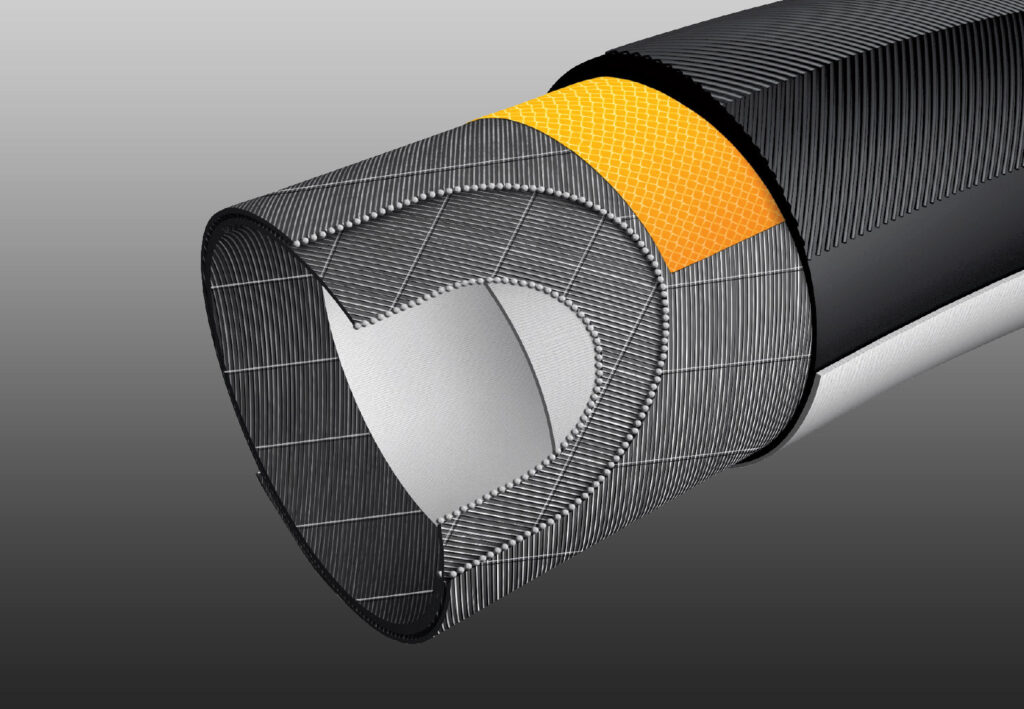

Here, we reveal some of the inner-most technology and revolutionary science behind the tires on your bicycle.